Our Services

Gold Hallmarking

Gold Hallmarking certifies the purity of gold as per BIS standards. Gold is tested by XRF or, when needed, fire assay for high accuracy. After testing, jewelry is stamped with the BIS logo, karat value (e.g., 22K916), hallmarking center code, and jeweler's mark.

This ensures purity, prevents fraud, builds customer trust, and is legally mandatory for selling gold jewelry in India.

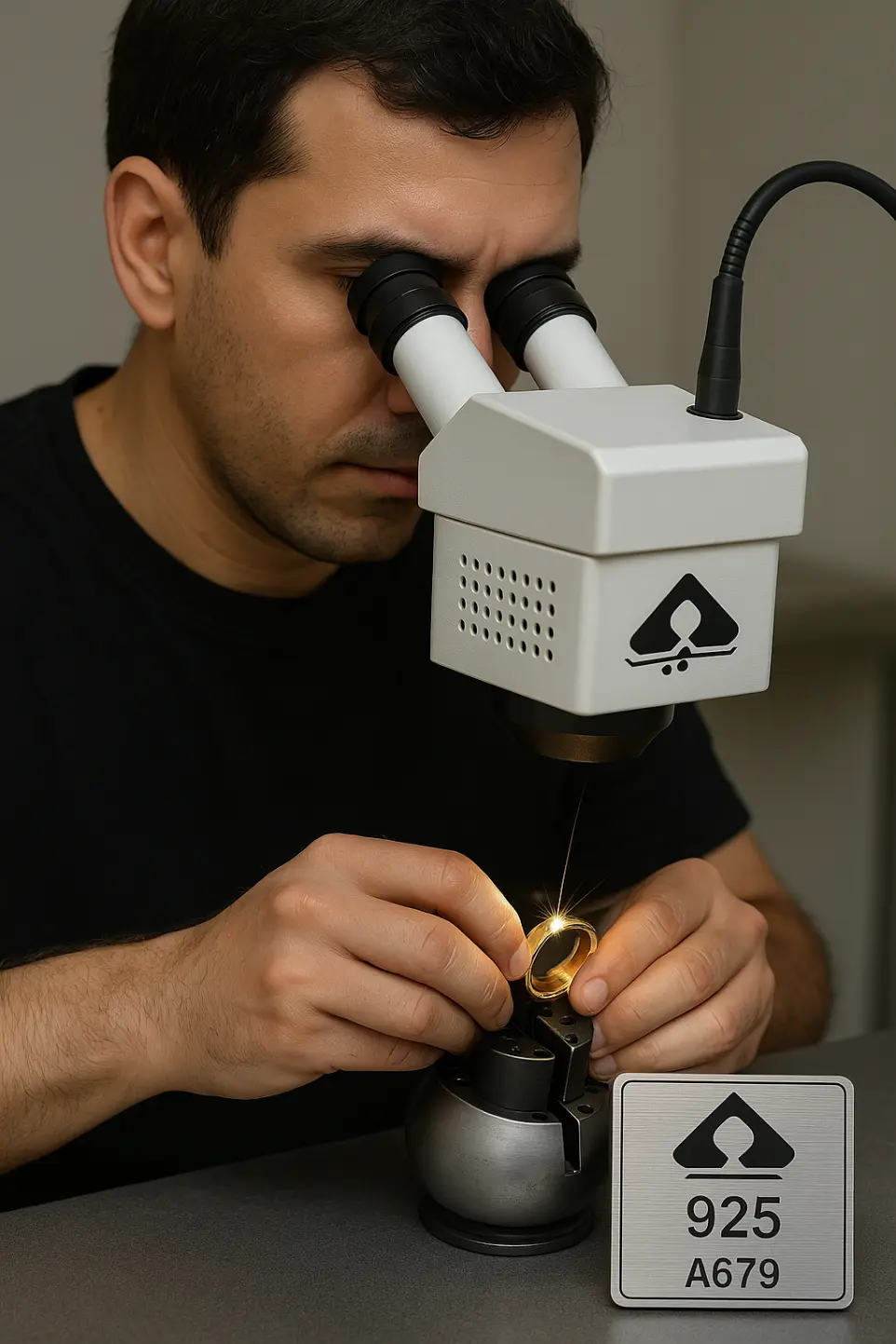

Silver Hallmarking

Silver Hallmarking certifies the purity of silver in jewelry, utensils, and other items as per BIS standards. Purity is tested using XRF, which does not damage the product. After verification, the item is stamped with a BIS hallmark that includes the BIS logo, purity mark (e.g., 925), hallmarking center code, and jeweler's mark.

Computer Touched Report

XRF (X-Ray Fluorescence) Testing is a fast, accurate, and non-destructive method to check the purity and composition of precious metals like gold, silver, and platinum. The machine uses X-rays to instantly identify elements and their quantity without damaging the item.

Widely used in hallmarking, XRF ensures metals meet BIS purity standards, helps detect fake or mixed metals, and is trusted for quality checks, customer verification, and certification.

Gold Fire Assay as per IS 1418

Fire Assay is the most accurate and trusted method to test the purity of gold and other precious metals. A small sample is melted at high temperatures in a furnace, separating impurities and leaving pure metal.

Though the process takes time and the sample is destroyed, it provides the highest precision and is widely used for hallmarking and legal certification.

Laser Solder Services

Laser Soldering is an advanced technique used in jewelry to join or repair small parts of gold or silver with high precision. It uses a laser beam to apply heat only where needed, making it ideal for delicate designs.

In hallmarking, it is often used after fire assay to restore items cut or slightly damaged during testing. This ensures the jewelry regains its original shape, strength, and finish, and is returned to the customer in perfect condition.

Silver Fire Testing as per IS 2113

Silver Fire Testing is a traditional and highly accurate method to determine the purity of silver. A small sample is melted at high temperatures, separating impurities to measure pure silver content.

Though slightly time-consuming and destructive, it provides results more precise than machine testing like XRF. It is widely trusted by hallmarking centers, laboratories, and industries where exact purity confirmation is required.

Photo Certificate

Photo Testing is part of the hallmarking process where a clear photo of each jewelry item is taken after testing and hallmarking. The photo captures the item’s design, size, and hallmark symbols (BIS logo, purity mark, jeweler's code, and center ID).

This acts as a digital proof to resolve complaints, verify items, and prevent fraud. Stored safely and shareable with BIS, it ensures transparency and trust in the hallmarking process.

Laser Marking/Engraving

Laser Soldering is a precise jewelry technique used to join or repair small parts of gold or silver without affecting the rest of the piece. It applies controlled heat only to the required area, making it ideal for delicate designs.

In hallmarking, it is often used after fire assay to restore items that were cut or slightly damaged during testing. This ensures the jewelry regains its original shape, strength, and finish, and is returned to the customer in perfect condition.